|

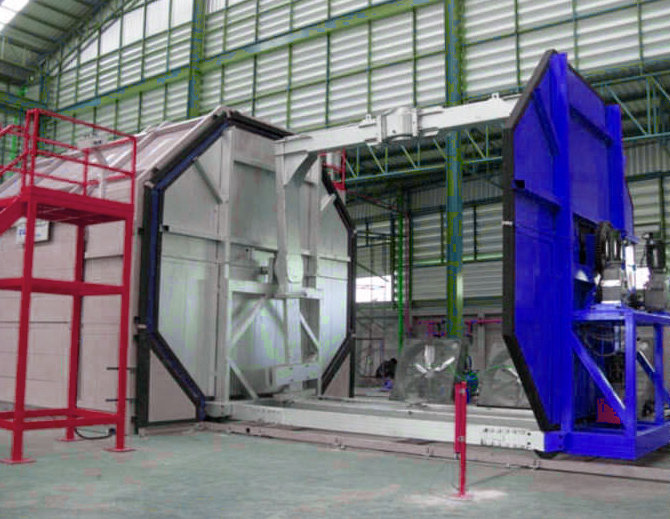

One Arm Shuttle Machine One Arm Shuttle Machine

|

|

|

|

One Arm Shuttle Machine is a rotational molding machine in which cooling and heating process takes place in several areas. It offers greater productive outputs as compared to clam shell machines. This machine offers at par manufacturing solutions for diverse range of plastic bottle applications, which includes high volume or short run production capabilities. Shuttle Machine works on electrical, hydraulic and mechanical processes and guarantees bulk production within a short span of time. The One Arm Shuttle Machine has PLC/PC motion control facility along-with controlled flash removal systems.

Specifications of One Arm Shuttle Machine:

- The Machine is configured with one or two cooling and load/unload stations along-with one oven.

- There is open cooling systems along-with floor level fans, and the option of closed cooling is also available.

- In order to handle heavy loads, carts are designed accordingly.

- The facility of offset arm is also available with arm closure.

- The machine has variable frequency speed control, which exerts pressure on motors, driving the minor and major axes.

- Per arm there is multi passage inner air system.

- Working platforms are advisable on larger machines, 3000mm and higher than that.

Advantages of of One Arm Shuttle Machine:

- The machine is configured for regular use and posses durable features. It is fabricated with grade-A steel frames in order to withstand high clamp tonnage, special trimming and fixed calibration.

- The Shuttle Machine has user-friendly operating screens and controls, which induces it easy start-up functions followed by diagnosis and production.

- Importantly, this machine has rapid production speed and hence results in improved outputs. With updated shuttle motion technology, the shuttle machine can perform multiple movements, which can be collectively results in faster cycle times.

- One Arm Shuttle Machine has faster mold changing ability, which keeps the production line running.

It has got die heads speed color changing ability and better versatility. In addition, standard and spiral sleeves make sure to offer rapid color changing option and accurate layering structures.

|

|

|

|

|

|