|

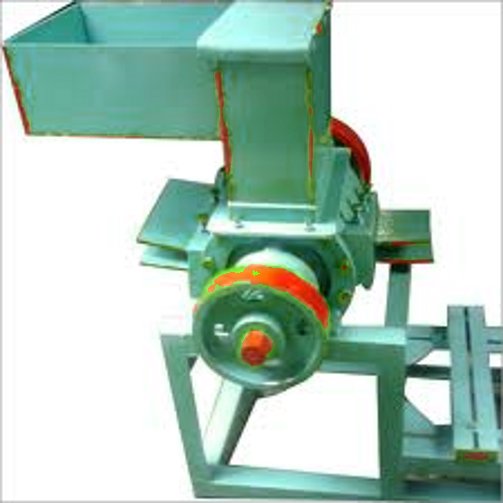

Plastic Scrap Grinder Plastic Scrap Grinder

|

|

|

|

Plastic Scrap Grinder is a machine used to grind various types of plastic materials/ articles like LLDPE, PP, RPVC, Pet Bottles, Plastic Chair Scrap, etc. The scrap grinder machine is available in different models and sizes to meet varied requirements of the buyers. The grinder is designed in sync with the state of the art technology so as to ascertain excellent mixing as well as consistent granules at low operating cost. Better mixing & closed control of the granular size results in faster tableting speed with least rejections.

Benefits of Plastic Scrap Grinder:

- Requires less maintenance and easy to operate

- Unique kind of grinding blade for the grinder

- Perfect Output of materials in accordance to the Scrap Grinder capability (for virgin materials)

The Granulator can be used for the milling associated with declined plastic items that are easily grinded into small pieces as per the mesh size. These grinded particles/ items can be used again for different applications. The Granulator is developed using large MS plates and sections. The opening part is easily modified through mounting bolts & nuts. Further, there is a hopper which is developed with the use of heavy MS plates, and is designed in a way that the materials cannot move out of the hopper during grinding process.

Grinding blades are the most important component of the Plastic Scrap Grinder, and ensure efficient processing of the materials. These are fabricated from premium grade special steel that is solidified and grounded for efficient working as well as long existence. The material and type of the grinding blade is chosen according to the item that is to be grinded. The position of the grinder blade is preset, and it guarantees efficient milling of the materials. Another component of the Plastic Scrap Grinder is Rotor, which is made from nitro alloy steel material and is dynamically well balanced to assure optimum performance.

Functional Features:

- Strong & huge metal body

- Procedure with much less vibration

- Greater result from less energy usage

- Long-lasting as well as upkeep free of the charge procedure

- Rotary knives made of unique steel, ensure efficient cutting angles for faster milling

- Wide selection in terms of machine type or versions

- Easy installation and maintenance

- Milling display, topside opening & content feeding connections

|

|

|

|

|

|