|

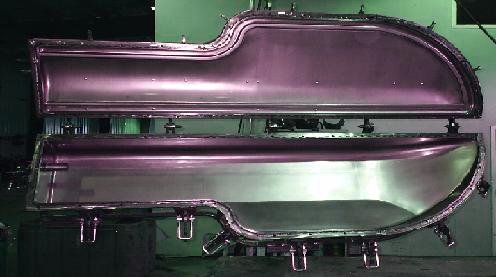

Sheet Metal Rotational Moulds Sheet Metal Rotational Moulds

|

|

|

|

Sheet Metal Rotational Moulds are most commonly used tooling methodology on large parts, which do not have complex designs and geometry. These tooling methods are cost-effective kind of rotational mold tooling and can be easily made within six to eight weeks depending upon the complexity of the respective design. Sheet Metal Rotational Moulds are formed and welded, the welds are then grounded and polished. These molds are available in various colors and finishes and are absolutely stress free and resistant to corrosion.

Importantly, Sheet Metal Rotational Moulds are a cost-effective way of getting the end-product in its perfect shape and design, without leaving any kind of scrap. The Sheet Metal Rotational Moulds are responsible for producing highly demanding end-product like brackets, plastic rotational molds and transport and electrical cabinets. These moulds works on advance technology and make sure to give the right texture and finish to the end-products as per industrial requirement.

Sheet Metal Rotational Moulds are fabricated from welded sheet or cast. The fabrication process is hugely goaded by part size, wherein the intricate parts are supposed to made out of cast tooling. Generally, the Sheet Metal Rotational Moulds are produced from aluminum and stainless steel. Meanwhile, aluminum molds are generally thicker as compared to steel mold, nevertheless, the thickness does not effect the cycle times as aluminum's thermal conductivity is way way higher than that of steel. In order to formulate a model for casting, cast molds have the tendency to lay effort on extra cost that are linked with production of tooling. However, fabricated aluminum or steel molds are less expensive when used for less complex parts. In some cases, molds comprises aluminum and steel as an ingredient, which induces the variation in thickness in the walls of the end-product.

|

|

|

|

|

|